AIoT Battery monitoring system

2. Improve the lifespan of individual batteries by automated management optimization with simple setting procedures.

3. Detect hidden defects and forecast the data in advance, avoiding critical situations happening.

4. Provide users with comprehensive data through powerful detecting functions and visualized scatter charts.

5. Compatible with a wide range of battery types as below:

1.2V/2V/4V/6V/12V Lead Acid (VRLA, VLA)/Lithium/NiCd/ NiMH Battery

BMS α-1 system includes battery monitoring and management system that both function by AIoT technology, also offering a way to access data through the Wi-fi hotspot and internet connection. With basic setup procedures, it can cyclically collect detailed data which comprise internal resistance(DCR), temperature, electromotive force, micro-discharge and float voltage, paving the way to know the actual condition of batteries with an even wider vision.

With specially designed BMS α-1 system, users can easily complement replacements or repairments depending on the degree of deviation that the system reports in notifications, which also would be shown on the screen, dry contact relay alarm, and sent by E-mail. Thus able to avoid potential risks caused by overcharging, battery deterioration, and power failure in advance. Most importantly, with the support of equalization(balancing) management, it’s able to maximize the service life of the battery system as a whole at a relatively lower cost, and so improve staff safety by decreasing direct contact with electric devices.

Main battery monitor management parameter:

1.【DC resistance】Analyze the level of grid corrosion, the non-wetting and strap rupture.

2.【Electromotive force】Analyze the problem of electrolyte deterioration, shortage between positive and negative plates and abnormal self-discharge.

3.【Float voltage】Analyze optimization and balance of charging voltage.

4.【Micro-discharge voltage】Test how long can battery maintain its voltage during discharging to make sure the ability of power supply during outage.

5.【Temperature】Prevent from thermal runaway.

Main functions of U-BUS Mini Workstation:

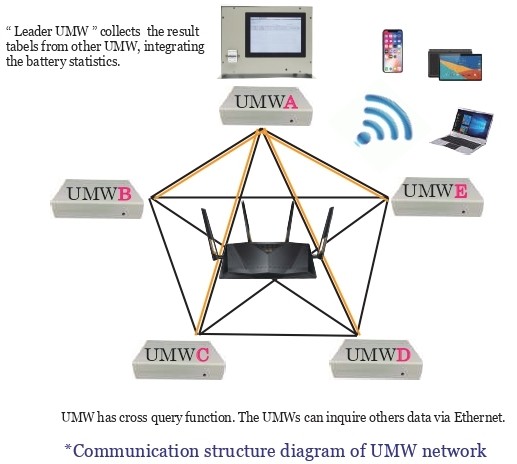

1.【Data collection and storage】The amount of battery and battery string can be edited to maximum of 254 stationary batteries by UMW.

2.【Result analysis and inquiry】Each UMW is proviede with on-site/ remote inquiry and cross query functions.

3.【Group management】Group management via assigned UMW, collecting the result tables from other UMWs. It also equips the hyper link inquiry functionl.

4.【Automatic time correction】Correct the time with time server.

5.【Hot spot inquiry】Except for the accessorial touch screen, the user also can set up the hot spot function, monitoring the report by mobile phone, tablet and notebook computer.

6.【Data connectivity】MODBUS TCP、MODBUS RTU (communications protocal ) are adopted。

7.【Alarm notification】Provied with dry contact and email alarm notification function.

8.【Automatic battery equalization】Raise the accordance of float charge voltage so the battery life is able to extend.

9.【Battery AI forecast】By analyzing the parameters to do the AI forecast.

Analytical report:

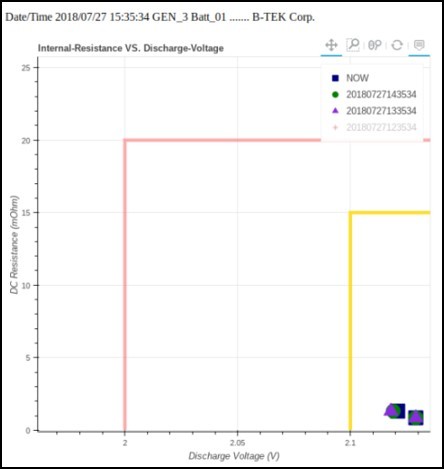

1.【Forecast scatter chart for battery life】

2.【Analysis of deteriorated parameters】

3.【Historical data inquiry and analysis】

4.【Color ard used to classify the statistics】

Battery spec that is applicable to the BMS α-1 :

1. Battery nominal voltage range: 0.9~16.0

2. Impedance resolution: 0.001mΩ, Impedance measurement rance: 0.05~50mΩ, suitable for capacity 7 to 3000Ah.

BMS α-1 - Battery Monitor System

why choose the BMS α-1 system from B-TEK?

UPS system as the important equipment to the stable power supply, needs great amount of battery as back-up power source. Due to the enormous amount of the batteries, it makes it hard to carry out the manual maintenance. To maintain the discharge ability during the outage, regularly manual detection is needed. However traditional battery discharge test needs battery offline. It’s time-consuming and increasing the cost. BMS α-1 system is able to improve the risk of manual measurement, battery deterioration and power failure, changing battery according to the actual condition of batteries. Besides, the automatic battery equalization function can extend the battery life. Not only can raise the reliability, lower the cost of battery failure, decreasing manual labor also increasing the stuff safety by avoiding the direct contact to the electric device.

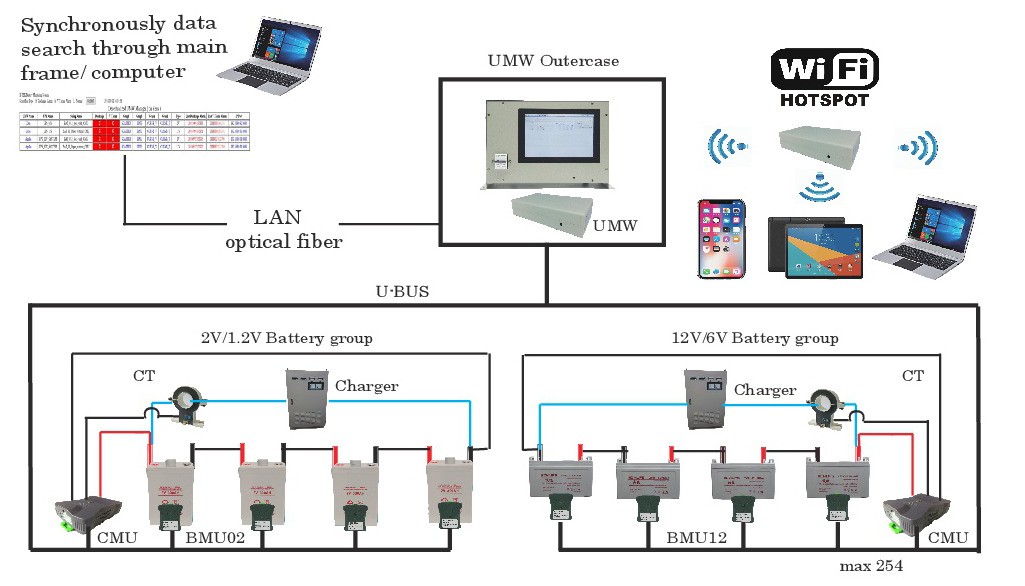

*BMS α-1 structure diagram

■ Main components of BMSα-1 system

BMU CMU UMW

Battery Monitor Unit Charger Monitor Unit U-BUS Mini Workstation

BMU is installed to the individual battery, collecting the data and send it to the UMW to analyze. Batteries supported (application)

nominal voltage range: from 1.2 to 12 volt industrial battery (measuring range 0.9 - 16V). The unit can be used on NiCd, NiMH, flooded and VRLA lead batteries. BMU is powered by the detected battery, therefore the extra power is not needed, This unit applies to a lead-acid battery, nickel-cadmium battery, lithium battery. BMU analyzes 5 parameters: terminal voltage, temperature, dc resistance, micro-discharging voltage, and electromotive force. Bu analysis, the system finds the deteriorated reasons for the battery and do the predictive maintenance. The groove on the back of BMU allows it to attach on the mounting rail. Dimension is 75*57*31mm. Reverse connection protection function will keep the internal circuit of BMU intact from a reverse connection.

CMU connects to the charger and UMW. The main purpose is to monitor the current of the charger and the total voltage of the battery bank. The groove on the back of the CMU allows it to attach on the mounting rail. Dimension is 75*57*31mm.

UMW provides the website browsing function, the user can access the real-time data, historical data, forecast scatter chart, line or curve graph through it. We can utilize a computer, mobile phone or tablet to remotely access the system through ethernet and hotspot function. Besides that, we can also use the FTP and VNC software to remotely access the data or control the system. When the system detects the abnormal parameter, it will automatically send the email notification and inform the users. Another AI function can provide a maximum of three years predicted data of the battery by analyzing the historical data. Efficiently manage the energy system.

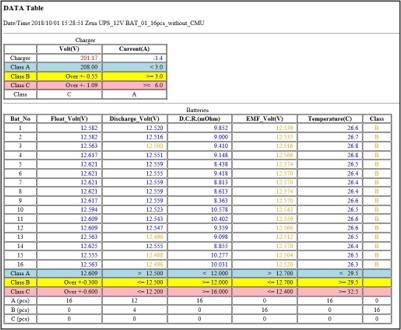

* Battery data tabe * Battery life predictive management chart

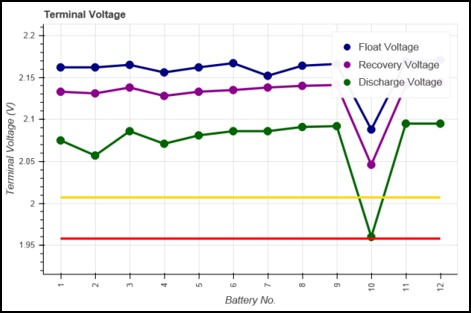

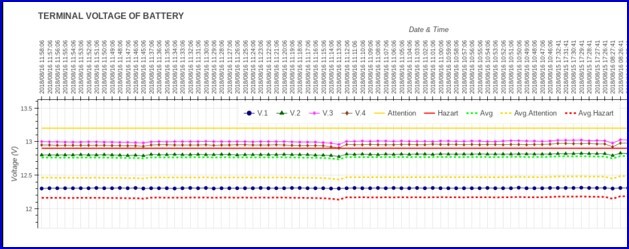

* Electric data line graph * Historical data curve graph

Tradewheel: https://www.tradewheel.com/p/battery-monitoring-system-bms-868515/

Worldtrade:https://www.eworldtrade.com/pd/btekcorp/aiot-battery-monitoring-system/739250/

-

AIoT BMS-2020 English catalog.pdf Download

■ Specification

BMU-Battery Monitor Unit

|

Type |

Nominal

volt.

|

Volt.

measuring

range

|

Temp.

measuring

range

|

DCR

measuring

range

|

Volt.

resolution

|

Volt.

accuracy

|

Temp.

resolution

|

Temp.

accuracy

|

DCR

resolution

|

DCR

accuracy

|

DCR

repeatability

|

Communication

baud rate

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

L type

|

1.2V/2V

|

1.9~3.0V

|

-10~70℃

|

0.05~11mΩ

|

0.001V

|

±0.5%

|

0.1℃ |

±1℃

|

0.001mΩ

|

±2%

|

±2%

|

9600

|

|

H type |

6V/12V | 5.0~16.0V | -10~70℃ | 1~50mΩ | 0.001V | ±0.5% | 0.1℃ | ±1℃ | 0.001mΩ | ±2% | ±2% | 9600 |

CMU-Charger Monitor Unit

|

Type

|

Volt. measuring

range

|

Total Volt.

resolution

|

Total Volt.

accuracy

|

Curren

resolution

|

Current

accuracy

|

Input

voltage

|

|---|---|---|---|---|---|---|

| CMU | 0~600V | 0.01V | ±0.25% | 0.1A | ±1%(F.S.) | +12V |

UMW- U-BUS Mini Workstation

| Type | Input Volt. | Operating Temp. range | Data output method |

Unit maximum connective amount |

Dry contact alarm | 10.1 inch touch screen | AI function |

Shortest scan time period |

Communication signal overvoltage protection | Output file |

|---|---|---|---|---|---|---|---|---|---|---|

| UMW | +12V | -10~70℃ |

ModbusTCP/IP Modus RTU Eternet(LAN) |

254 | 4*1a1b | with | with | 10 sec. | DC/AC 1000V | CSV file |

AIS

Automatic Integration Software

| AIS | |

| Automatic integration software | ● |